SURFACE MATERIAL

Introduction

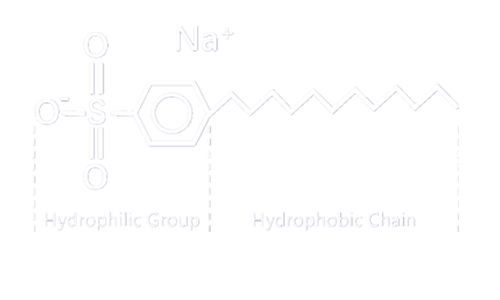

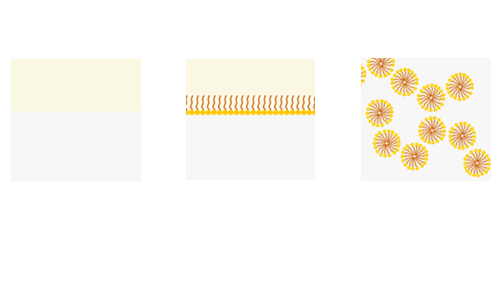

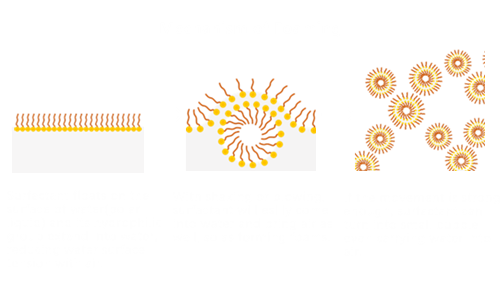

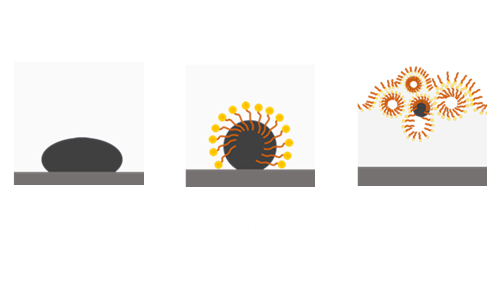

Surface is the professional name calling the obvious contacting area of different phases such as liquid-air, solid-liquid and solid-air, or the boundary of two immiscrible liquids(or more professionally call interface). Surface material(surfactant) is just the substance can effectively change that area. As said in biobased material page, surfactants are mostly made from alkane or fatty acid after alternating or adding hydrophilic group so can show two opposite properties. The original hydrocarbon part is friendly to oil(nonpolar liquid insoluble in water) while the altered part is water(polar liquid). As the result, each part will stretch into different phase and significantly reduce interface tension--it's the integrative manifestation of the force trend that one phase's boarder molecules want to gather together due to they are seperated by other phase's molecules--thus bringing many interesting phonomenon such as solubilizing, foaming, flotating, cleaning, etc.

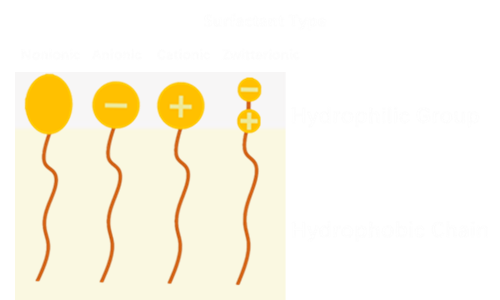

According to its ionicity, surfactant can be included into four classes: anionic one, cationic one, nonionic one and zwitterionic one. Anionic surfactant is the easiest made type as well as largest produced one, while cationic surfactant is suitable for daily use, personal care and disinfectant products. Nonionic surfactant is well compatible to both anionic and cationic systems and can be a helpful complement, while zwitterionic one is a superior type owning both ions. It can be applied in uncertain and strict conditions. Surfactant is a very useful material that not can be applied directly, but also an important agent for emulsification polymerization.

Anionic Surfactant

Anionic surfactant is simply made from acidating alkane(or modified alkane) then neutrilize, or directly alkaline hydrolyzing fatty acid. It can be mainly devided into sulphate type, sulphonate type, carboxylate type and phosphate type. Usually made in solid form like soap and washing powder and used as home and industrial detergent, while some types like calcium/potassium/zinc stearate can be applied in food and rubber as well. Some

Anionic surfactant is powerful in cleaning, however there're also disadvantages. It will react and loss effect when meat hard water(water contains many metal cationic ions) and most times can't mix with cationic surfactants. It is also sensitive to PH(since H+ is also cationic ion), types like carboxylate and sulphate surfactant will even seperate out hydrophilic group and decompose.

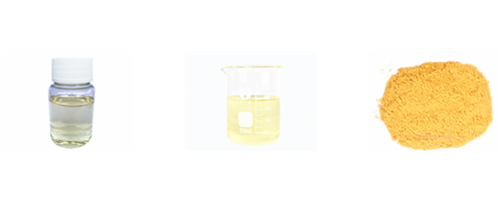

We supply common anionic surfactants like SDS(sodium dodecyl/lauryl sulfate, also name K12), LAS(sodium lauryl sulfonate), SDBS(sodium dodecyl benzene sulfonate, also name sodium linear alkane benzene sulfonate/LABS), LABSA(dodecyl/lauryl benzene sulfonic acid, raw material for SDBS), SLES(sodium lauryl ether sulfate), stearate, etc. We can also provide detailed recipe for detergent as well as suggestions.

Cationic Surfactant

Cationic surfactant is a less used type compared to anionic and nonionic surfactants, however still plays important role in speical demanding places. Contrary to anionic sufactant, cationic one is neutralized by acid and usually sensitive to alkaline. It is not suitable for detergent because base material like fabric usually shows anionic, cationic surfactant's hydrophilic group will be attracted and stay on the object. However it can be used as antistatic agent and softener/finisher for clothes. Interestingly, our skin and hair show cationic, so cationic surfactant is widely used in shampoo and bath lotion as cleaner and protecter. Since it can also effectively attached on bateria and prevent its breathing, it's also an effective bactericide.

Cationic surfactant can be devided into amine salt, quaternary ammonium salt, other onium salt and heterocyclic cationic surfactants. Amine salt is the simpliest type made from reacting primary/secondary/tertiary amine with acid, they are commonly used as mineral flotation agents and raw material for zwitterionic surfactant. Quaternary ammonium salt is the mostly used one in daily-used product, textile, bactericide and won't affected by alkaline. Onium salt like sulfonium or phosphonium salt is applied as supplement for bactericide as well as special pesticide and plant's growth regulator. Heterocyclic types like pyridinium, morpholine and imidazolinium are also commonly used as bactaericide, or for speciallized purposes like dyeing assistant, antirusting agent, corrosion inhibitor and water repellent, etc.

Hosome provides full kinds of cationic surfactants especially the quaternary ammonium one. We are expert of alkyl trimethylammonium chloride, dialkyl dimethylammonium chloride and alkyldimethyl benzylammonium chloride.

Nonionic Surfactant

Nonionic surfactant is another big type, nowadays output is close to anionic one. It has high stability and excellent compatibility to other three types of surfactants. Ions have little influence on its performance leads strong tolerance to hard water. It can give water lower surface tension than other surfactants which makes it very suitable for solubilizer and emulsifier in emulsification polymerization. However some of its properties are very different from ionic surfactants, like solubility won't increase when temperature rises but opposite, which should be aware in actual using.

Like other surfactants, nonionic one can be also included into several types. The commonest is polyethylene oxide surfactant which is easily made by reacting ethylene oxide(EO) with fatty acd, fatty alcohol or alkylphenol. The open-ringed ethylene oxide is just the hydrophilic side and solubility in water can be controlled by EO's quantity in the molecule(hydrophilic group length). That's also the reason why PEG(polyethylene glycol, just made from homopolymerizing EO) can be taken as surfactant. Sometimes we can also acidify it to make anionic surfactants(like SLES). Another main type is polyol surfactant. It's made from polyol(or other chemical has multiple hydroxyl groups like glucose) esterifying fatty acid and the surplus hydroxyl group brings hydrophilicity. Since it has low toxicity, detailed products like Span can be used in food and drugs. To increase its solubility, we can even secondary PEGylate it(like Tween is PEGylated Span) or acidify it. Third type is polyether surfactant, it's a newly developed polymerized kind that uses alcohol reacts with two or more kinds of alkylene oxide(epoxide) not only EO. In fact it's an oligomer can be named as polyether alcohol and its wetting ability, cleaning power, foaming ability, etc could be adjusted by the kind and length of different alkylene oxides. For some special types, since their foaming ability lower so much, they can be even used as defoamer.

Only one nonionic surfactant usually can't achieve best solubilizing effect due to discordant HLB value. When used as complement, the coordination to other inonic system will also be poles apart according to the type chosen. And even for same product name, there're difference in reacting degree and EO length which makes their perfomance totally diverse. Hosome is not only manufacturer, but also proficient in our products' properties.

Zwitterionic Surfactant

Zwitterionic surfactant's hydrophilic group can be divided into two parts: one part is anionic and the other part is cationic, so when PH changes, zwitterionic surfactant will just show different ionicity but not easily lose effect(however when PH is around 7, it might precipitate instead). Like nonionic surfactant, zwitterionic one is resistant to hard water and compatible to other ionic surfactants. It can lower other surfactant's stimulation so often used in daily-use products. Since its price is relatively high, besides daily use, zwitterionic surfactant is more recommended in complex and changeable conditions like oil drilling site.

Amine oxide is a simpliest type that made from oxidizing alkyl tertiary amine(or modified one). The nitrogen becomes cationic and oxygen is anionic, however later one is very week so sometimes it can be also considered as cationic surfactant. Comparing to cationic quaternary ammonium surfactant, it has better compatibility with anionic product. It serves like nonionic surfactant which increases thickness while also reduces irritating and static happening. Amino acid is another simple type that uses primary amine then hydrolyzing by acidifier like methyl acrylate(β-alanine type) and sodium chloroacetate(α-glycine type). It is usually used in cosmetics and personal care products.

Betaine surfactant is one main zwitterionic type. Betaine's formal name is (carboxymethyl)trimethylammonium salt which carboxymethyl group shows anionicity and trimethylammonium shows cationicity. Betaine surfactant is not made from fatty oil directly reacting with betaine but by two steps to get betaine's structure--first step is to make alkyl tertiary amine then quaternarize by monochloroacetic acid. The acid and amine could be adjusted so can get modified types like alkyl hydroxypropyl sulfobetaine and alkyl amidopropyl betaine. All betaine surfactants don't exist precipitation and modified types can be further used in extreme PH value.

Imidazoline surfactant is another main type. The producing method is very same to alkyl amidopropyl betaine, however adds one dehydrorating process before acidizing to form ring structure. It has even lower stimulation and well bio-degradation. Lecithin is a totally nature zwitterionic surfactant(we've also introduced in biobased material page) made from soybean. It's mostly applied in pharmaceuticals, food and cosmetics.

Special Surfactant

Silicone surfactant and fluoride surfactant show varieties comparing to traditional surfactants so we commonly classify them into special kind. Silicone surfactant is carbon bone partly displaced by silicon-oxygen bone(and sometimes the silicon-oxygen bone is verticle to main chain--in fact it's common surfactant modifies silicone oil as we introduced in polymer page) while fluoride one is fluorine replaces hydrogen which attached to carbon bone. They can also be concluded into four ionic types--the manufacturing mechanism is usually same--however performance shows quite difference and applied in other places or for diverse purpose.

Since silicon-oxygen bone is neither hydrophilic nor attractive to common hydrocarbon oil, silicone surfactant can be used in emulsifying special oil like silicone oil. It also makes emulsion very stable even in existance of demulsifier like ethanol(ethanol itself is unpolar liquid however can solve in water due to hydrogen bond, thus makes common surfactant's hydrophobic side easily lose effect.) This structure brings low surface tension and super wetting ability as well which keeps moisture even on very hydrophobic surface and makes it very suitable for clothes finisher, cosmetics and herbicide emulsifier.

Like silicone surfactant, fluorine surfactant's fluorinated alkyl chain is also alienate to both water and oil and can be used as emulsifier for polytetrafluoroethylene(PTFE/Teflon). And its hydrophobic property is much stronger than alkyl chain leads it quickly form monomolecular layer on water, using only little fluorine surfactant can produce plenty foams. It is also stable to extreme condition like high temperature, so widely used in extinguisher, oil drilling site, chrome plating, etc.