PHASE CHANGE MATERIAL

Introduction

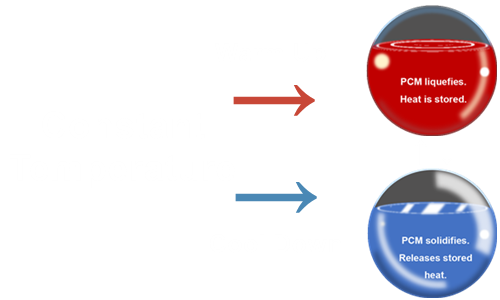

The main usage of phase change material is to store heat to keep the temperature constant. Mechanism is shown as below: when temperature of outside rises up, the material starts to melt(phase change), in microscopic the molecule forming material becomes disordered thus absorbing a certain amount of heat before changing its own temperature, which retroacts to maintain the small environment a steady temperature; vice versa.

In fact nearly all materials have this "phase change" property(like water), however only specific types can store considerable heat to put into commercial operation as well as cheap enough to cover cost. After years finding and developing, Hosome is glad to introduce those high performance material with low price to people.

Organic Phase Change Material(OPCM)

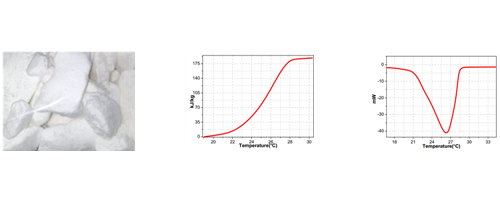

The main component of organic PCM is alkane, according to purity and producing process we classify it into phase change wax and n-alkane two main kinds. N-alkane is purer one, according to name it's just composed by n-alkanes like C18(n-octadecane). One n-alkane has fixed phase change temperature, by mixing different n-alkanes together we can get accurate phase change temperature we want with steady property. Phase change wax(we also name it PCW) is refined from paraffin wax, besides n-alkane it also contains some branched alkanes.

Both n-alkane and PCW have stable properties, comparing to inorganic PCM they don't need to be sealed. They don't have undercooling point and own a long life. Its latent heat is also larger than most inorganic ones. The only disadavantages are low thermal conductivity(however could be improved by adding metal or increasing contact area) and relatively high price. Commonly n-alkane is used in more strict places like laboratory, drug transportation or producing microcapsule, PCW is applied widely in industry, construction, devices, etc.

Inorganic Phase Change Material(IPCM)

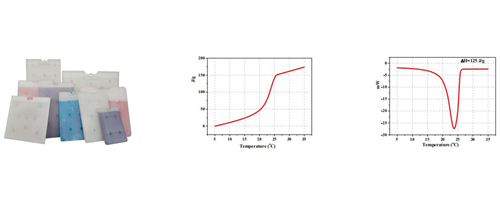

Inorganic PCM consists of inorganic salts, nuleator, water and other additives. Since most inorganic salt is hydrous one and will lose effect if crystal water disappears, inorganic PCM has to be sealed in container like HDPE flat barrel.

Because inorganic salts can get easily from nature, IPCM is often cheaper than organic ones. It could also be designed among a wide range of phase change temperature from -100℃ to 1000℃. Some types' latent heat is even higher than organic PCM. Undercooling phenomenon is IPCM's disadvantage, however our unique formula can control the actual difference within 1℃. And though its life is shorter, we can ensure more than 20000 times of cycling which leads industrial application possible and profitable.

More Products

· Microcapsule and Phase Change Cloth

We can make nanometer grade microcapsule contains PCM in shell. These small particles will distribute evenly in fiber after sizing and we can get phase change cloth which has very comfortable body feel. It's a high-class advanced fabric even used in spacesuit.

· Other Composite Material and Final Product

By sizing PCM(usually organic one) on paper, mixing with wood chips, putty or concrete, we can get other composite materials which can keep solid. They could be directly used in fields like construction without considering container. PCM could also be incorporated into other high molecule material to make heat conducting resin so as to substitute traditional silicone grease in CPU and lithium battery as well as other electronic devices.

· Customized Package and Cold/Heat Sink

For PCM's container we can provide nearly all types no matter it's ice bag, foil bag, HDPE flat barrel or plastic ball. Their size could be customized according to customer's demand. For other relative equipments we can also supply such as incubator, cold and heat sink or full set of energy saving facility.